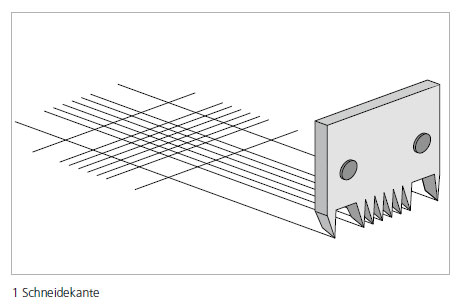

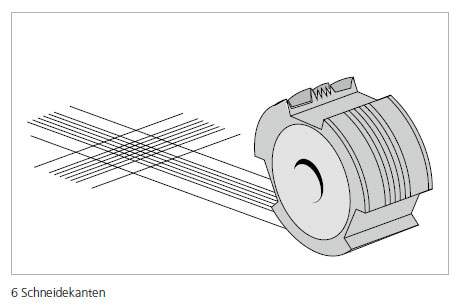

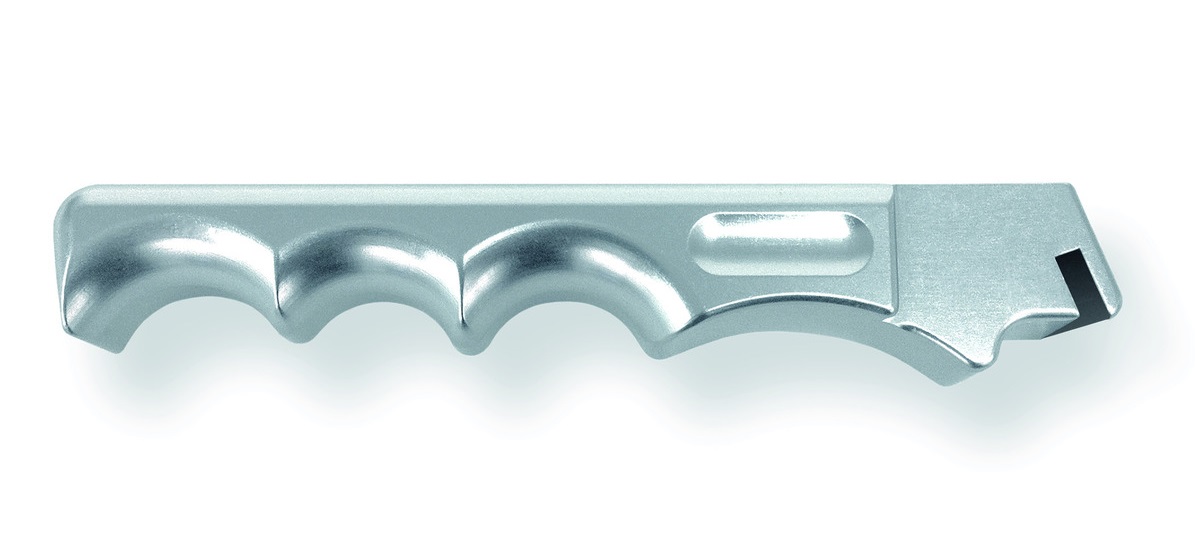

Cross Hatch Adhesion Kit

This method is used for determining the parallel groove paint adhesion of one or many layers on a substrate, generally a metal panel. The Cross Cut blades are

made of hardened steel alloy and are designed for retaining a sharp cutting edge to reduce the frequency of blade replacement.